If you’ve ever tried your hand at wood burning for biochar, you might have wondered about a crucial aspect – where should the heat be concentrated?

When burning wood for biochar production, the heat should be concentrated at the top of the wood pile to ensure optimal pyrolysis and prevent the bottom from turning into ash. This strategic heat concentration is vital for transforming wood into biochar without compromising its quality. It involves selecting the right wood type, ensuring proper ventilation, and monitoring the burning process for even heat distribution. By mastering heat concentration, you enhance your ability to produce high-quality biochar effectively.

Join me in this article where I will uncover the practicalities of this process

The Science Behind Wood Burning for Biochar

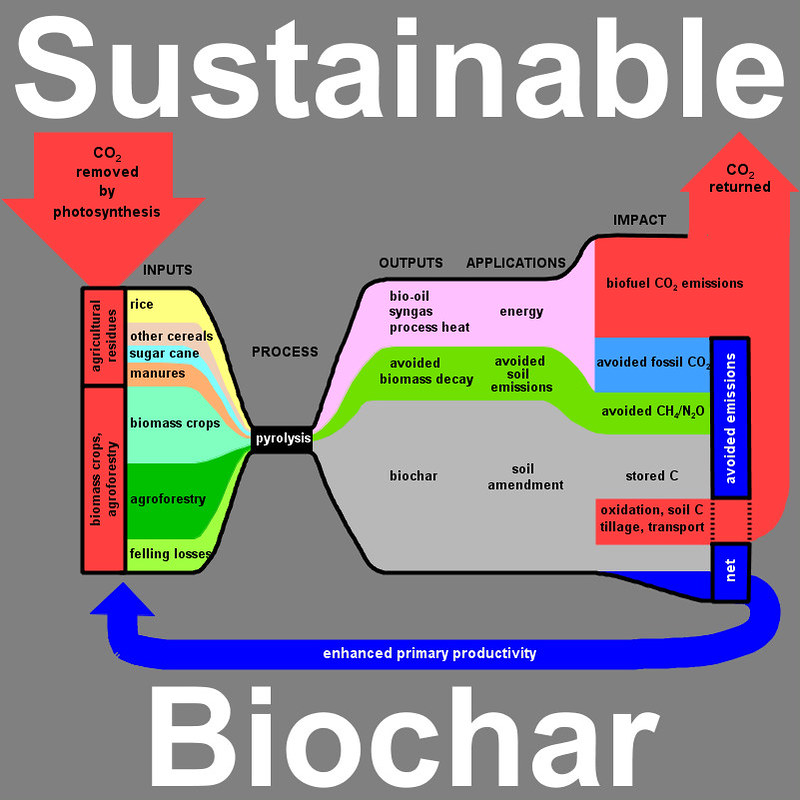

Biochar is the result of a process where organic material, in this case, wood, undergoes slow pyrolysis, a low-temperature decomposition in the absence of oxygen. This transformation turns the wood into a stable form of carbon, creating biochar.

The role of heat in this process is pivotal. The heat triggers a chemical reaction in the wood, breaking it down into biochar while releasing volatile compounds. However, if not managed properly, this heat can pose risks, particularly in terms of uneven distribution, leading to the bottom burning to ash.

One of the challenges in wood burning for biochar is the potential for the lower layers to turn into ash. This not only diminishes the overall yield but also affects the quality of the biochar produced. It’s like cooking a dish where the bottom layer burns while the top remains undercooked – not the desired outcome.

The Importance of Heat Concentration

Understanding why heat concentration matters is crucial. The goal is to find the sweet spot, a balance where the heat is intense enough to trigger the pyrolysis process but not too excessive to turn the wood into ash. This delicate equilibrium directly impacts the success of biochar production.

The challenge lies in achieving the delicate balance required for optimal biochar production. This involves strategic heat concentration, ensuring that the entire wood heap undergoes pyrolysis uniformly. It’s akin to walking a tightrope, where any imbalance can lead to undesired outcomes.

The quality of biochar is directly linked to how well the heat is concentrated during the burning process. Properly concentrated heat results in high-quality biochar with optimal carbon content, making it an effective soil amendment.

Practical Tips for Concentrating Heat

Choosing the Right Wood

Not all woods are created equal when it comes to biochar production. Selecting the right type of wood is crucial for achieving optimal results. Dense hardwoods with minimal resin content are your go-to choice. Hardwoods such as oak, maple, or hickory are ideal candidates for biochar production. These woods provide a solid carbon structure without introducing excessive impurities.

On the flip side, softwoods and woods treated with chemicals should be avoided. Softwoods contain higher resin levels, which can result in the production of harmful by-products during pyrolysis. Chemical-treated wood can introduce toxins into the biochar, rendering it unsuitable for soil enhancement.

Remember, the quality of your biochar starts with the wood you choose, so make a wise selection.

Proper Stacking Techniques

The Importance of a Well-Ventilated Heap

Creating a well-ventilated heap is a fundamental aspect of successful biochar production. Adequate airflow is essential to ensure that the heat generated during the burning process is evenly distributed throughout the wood pile. Think of it as providing oxygen to a fire – without it, the combustion process falters.

To achieve proper ventilation, consider the following:

- Stacking Configuration: Arrange the wood in a way that allows air to circulate freely. Avoid tightly packed configurations that restrict airflow.

- Stack Height: Build your heap to a reasonable height, allowing air to reach all parts of the pile. This prevents the formation of pockets with inadequate oxygen supply, reducing the risk of incomplete pyrolysis.

- Use of Supports: Elevate the wood pile slightly to create space underneath, facilitating airflow from the bottom. This simple technique can enhance the overall efficiency of the burning process.

By prioritizing ventilation, you ensure that every piece of wood undergoes pyrolysis uniformly, preventing hotspots or areas devoid of the necessary oxygen.

Layering and Organization for Optimal Heat Flow

Careful layering and organization of the wood within the pile contribute significantly to optimal heat flow. Picture it as arranging logs in a fireplace – a strategic placement that maximizes the efficiency of the burning process.

Consider the following tips:

- Size Matters: Use a mix of wood sizes, including larger logs and smaller branches. This variety promotes better airflow and helps maintain a consistent temperature throughout the pile.

- Alternating Layers: Arrange the wood in alternating layers of different sizes. This pattern facilitates air movement, preventing the formation of dense pockets that impede heat distribution.

- Avoiding Compaction: While it may be tempting to tightly pack the wood, avoid excessive compaction. Allow some space between the pieces to promote air circulation, ensuring that each log receives its fair share of heat.

In essence, proper layering and organization set the stage for an efficient and uniform pyrolysis process, leading to the production of high-quality biochar.

Monitoring and Adjusting the Process

Regular Checks During Burning

Frequent checks during the burning process are necessary. Observing the color and condition of the wood’s surface helps determine when to add more wood or adjust the heat concentration.

Interventions to Correct Heat Distribution Issues

If uneven heat distribution is detected, interventions such as rearranging the wood or adjusting airflow can correct the issue. This trial-and-error process is part of mastering the art of wood burning for biochar.

Common Mistakes and How to Avoid Them

Overlooking the Importance of Heat Concentration

Common Mistake: Many aspiring biochar producers underestimate the critical role of heat concentration in the wood burning process. It’s easy to assume that any fire will do, but neglecting the importance of maintaining the right heat level can lead to undesirable outcomes.

How to Avoid:

- Monitor Consistently: Regularly check the burning process to ensure that the heat is concentrated at the optimal level. Visual cues, such as the color of the wood’s surface, can provide insights into the heat distribution.

- Adjust as Needed: If you notice uneven heat or areas where the concentration is too high or too low, intervene promptly. Adjust the arrangement of the wood, add more fuel strategically, or modify airflow to correct the issue.

- Learn from Experience: Each wood burning session is a learning opportunity. Pay attention to how different wood types and stacking configurations impact heat concentration. This hands-on experience contributes to refining your biochar production skills over time.

Using Unsuitable Wood Types

Common Mistake: Selecting the wrong type of wood is a surprisingly common mistake in biochar production. Not all woods are created equal, and choosing the wrong variety can result in a subpar biochar and even pose environmental risks.

How to Avoid:

- Research Wood Types: Before starting a biochar project, familiarize yourself with the characteristics of different woods. Opt for hardwoods like oak, maple, or hickory with minimal resin content. Avoid softwoods and chemically treated woods, as they can introduce impurities and harmful substances into the biochar.

- Ask for Expert Advice: If in doubt, seek advice from experienced biochar producers or local experts. They can provide valuable insights into the best wood types available in your region and tips for making informed choices.

- Test Small Batches: Conduct small-scale trials with different wood types to observe how they behave during the pyrolysis process. This empirical approach allows you to assess the quality of biochar produced from various woods.

Ignoring Ventilation and Airflow

Common Mistake: Disregarding the importance of ventilation and airflow within the wood pile is a pitfall that can undermine the entire biochar production process. Inadequate oxygen supply hinders the pyrolysis process, leading to incomplete biochar production.

How to Avoid:

- Prioritize Airflow: Make proper ventilation a top priority when building your wood pile. Ensure there is enough space between logs and branches to allow air to circulate freely.

- Elevate the Pile: If possible, elevate the wood pile slightly to create space underneath. This simple step facilitates airflow from the bottom, preventing pockets of stagnant air.

- Adjust Stack Height: Pay attention to the height of your wood pile. A moderate height allows for efficient airflow, preventing areas of the pile from being oxygen-starved.

- Regularly Inspect Airflow: During the burning process, periodically check for signs of uneven airflow. Adjust the pile if necessary, ensuring that each part receives sufficient oxygen for optimal pyrolysis.

By avoiding these common mistakes and embracing best practices, you enhance your chances of successfully producing high-quality biochar while minimizing resource wastage and environmental impact. Remember, the journey to mastering wood burning for biochar is marked by continuous learning and refinement.

Conclusion

In conclusion, the key to successful wood burning for biochar lies in understanding and mastering heat concentration. It’s the puzzle piece that ensures the transformation of wood into high-quality biochar without losing its essence.

To those intrigued by the prospect of creating biochar, I encourage you to embark on this journey armed with newfound knowledge. Remember, it’s a trial-and-error process, much like learning to ride a bike or cook a perfect meal.